Towards more flexible hydropower: preventing turbine instability during multiple start/stop procedures

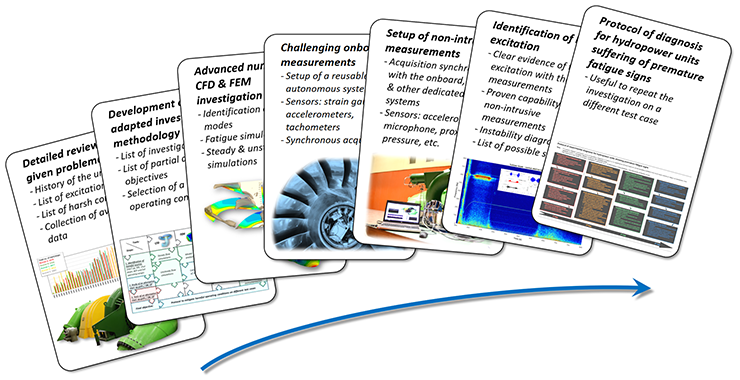

This study performed within the FlexStor-WP5 project allowed us to identify the critical operating conditions that had led to the premature fatigue of the turbine runner from Grimsel 2 power plant. We concluded that those conditions had developed due to a drastic increase in the number of daily starts and stops in recent years. In the end, we synthesized our findings in a protocol of experimental diagnosis for hydropower units showing premature fatigue signs. This smart diagnostic tool is also useful for other machines with similar problems.

The Hydroelectricity research group from the HES-SO Valais-Wallis has been in charge of the FlexSTOR-WP6 project in the SCCER-SoE (Work Package 5). The activities performed in this project, together with Kraftwerke Oberhasli (KWO) and the Laboratory for hydraulic machines at EPFL (EPFL-LMH), aimed at investigating the impact of frequent start-up and stand-by operations on hydraulic machines using cutting-edge numerical and experimental approaches.

The study focused on a 100-megawatt Francis turbine prototype, part of one of the four horizontal ternary groups of Grimsel 2 pumped-storage power plant in Switzerland. Due to a drastic increase of daily starts and stops in the recent years, cracks had developed in the runner blades of the Francis turbines, without a clear explanation for the phenomenon responsible for their onset.

The setup to understand why the cracks developed

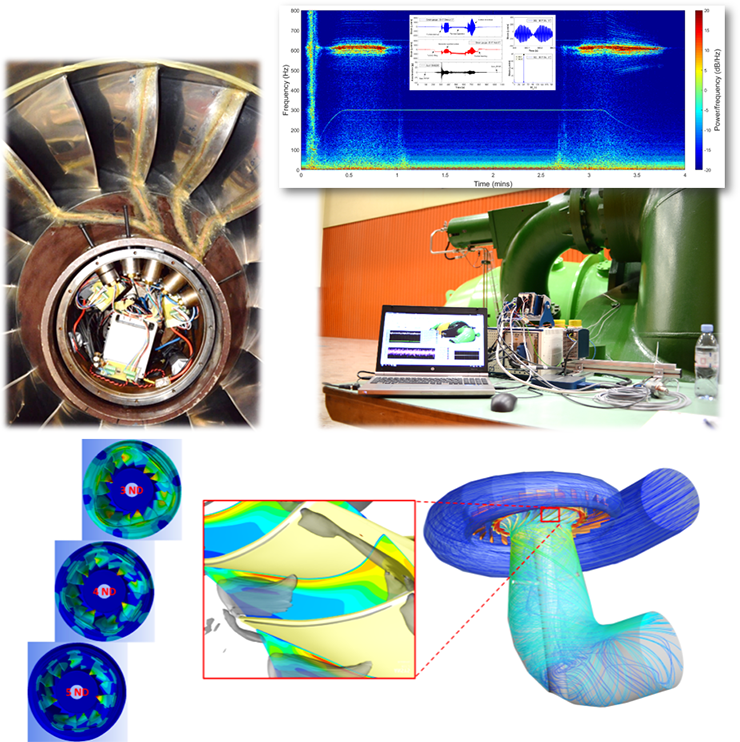

The purpose of this study was to identify the operating conditions responsible for these cracks, on a complete start-to-stop cycle, including the full operating range from deep part-load up to full load. To this end, we conducted an in-situ experimental investigation using two synchronised sets of measurements: the first one consisted of onboard measurements while the other one consisted of external non-intrusive measurements.

For a given upper and lower reservoir level, our experiment covered the full turbine hill-chart during the measurement campaigns: start-up, speed no-load, deep part load, best efficiency point, full load and shutdown operating conditions. The onboard instrumentation, which was the more challenging one of the two, consisted of strain gauges attached to the runner blades and accelerometers and tachometers placed in the centre of the runner (in the same location as the acquisition system). The external non-intrusive instrumentation consisted mainly of accelerometers, a microphone, shaft vibration transducers and a tachometer, along with an upstream and a downstream pressure sensor, as well as an ultrasonic flowmeter.

A numerical study to complement the measurements

To complete the investigation of this challenging phenomenon puzzle and, in the end, to provide a solution, we conducted a complementary numerical study. We carried out Computational Fluid Dynamics (CFD) numerical simulations of the fluid flow through the turbine for different operating conditions and a Finite Element Method (FEM) structural and modal analysis of the runner.

We identified the critical conditions…

Based on the onboard measurements, we evidenced that the highest mechanical stresses on the runner blades occur at speed no-load operating condition during the synchronization of the machine with the network and during the shutdown. Then, we computed the eigenmodes (the natural vibration of an object) of the turbine runner by FEM modal analysis and we estimated their deformation and the mean stresses due to the flow pressure with the help of the one-way coupling between CFD and FEM.

Compiling all the experimental and numerical information, we succeeded to provide the following scenario for the onset of the harmful conditions: one of the eigenmodes of the runner is partially excited during these operating conditions. This leads to the fatigue limit overtaking and to the incipience of cracks.

…and developed a diagnostic tool to prevent them

We also demonstrated that it is possible to successfully identify the critical instability operating conditions by using only non-intrusive measurements on the stationary frame. In the end, we synthesized our findings in a protocol of experimental diagnosis for hydropower units showing premature fatigue signs. This tool is also useful for other machines with similar problems.

Blog Article

This article is now availabe in the SCCER-SoE blog in German, French and English with more detailed biographies of the authors.