Mont Terri Experiment: Studying Caprock and Fault Sealing Integrity

August 2018 - by Alba Zappone, Michèle Marti & the SCCER-SoE team

Is CO2 safely sealed underground, in case of faulting in the caprock? Storing CO2 underground and thereby reducing emissions above ground is an interesting option. A compelling requirement for its success is to avoid leakage. The CO2 needs to be safely stored for decades. Within ELEGANCY, we will experimentally investigate how well a rock with faults can retain CO2.

There are two main paths CO2 could potentially take to escape from the reservoir it has been deposited in.

- One is the borehole used to pump in the CO2,

- the other are natural faults in the rock formation above the reservoir meant to seal it.

In our experiment, we focus on such faults, because they might not only influence the long-term containment of CO2, but also the occurrence of induced micro-seismicity. The presence of faults in the capturing rock therefore strongly affects the site characterization process in terms of safety/risk assessment, monitoring, verification, and with respect to the risk management plan.

Leakage not fully understood

Currently, the physical parameters governing leakage through faults is not fully understood. The behaviour of faulted rocks exposed to a CO2-rich fluid is a challenging topic for scientific research.

Although numerical simulations of CO2 migration along faults are progressing, CO2-specific experimental data, especially coupling geomechanical and geochemical interactions, is still missing.

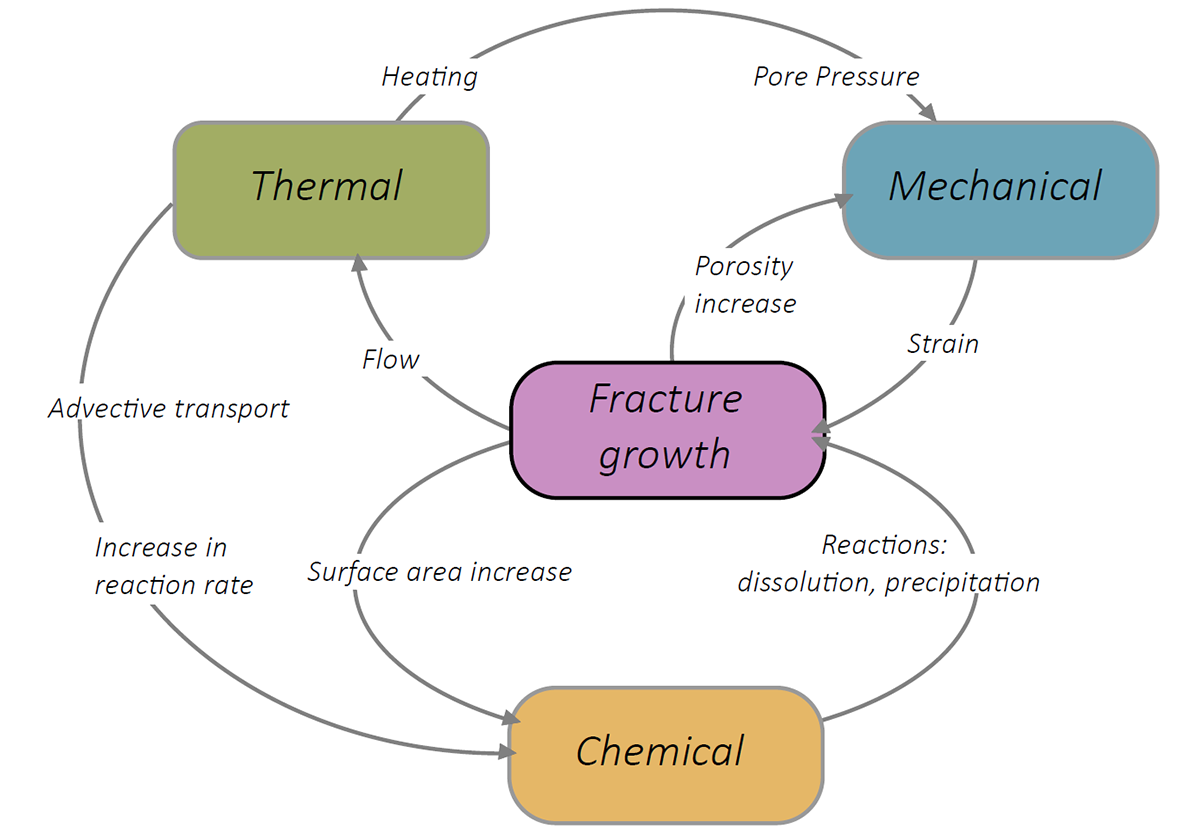

The growth of a fracture is a complex process interconnecting thermal, mechanical, and chemical processes (see Figure 1). For example, the increase in temperature due to slip and friction within a fault causes local pressure changes and augments the rate of reactions associated to fluid-rock interaction. Consequently, the dissolution of primary and precipitation of secondary minerals will affect the porosity, which in turn will alter the permeability and thereby the fluid flow. How reactive fluids such as CO2 enriched salt water influence these processes is currently not well understood.

Figure 1: Schematic of the coupling of fracture growth with mechanical, chemical, and thermal processes; these mechanisms compose a feedback relationship displaying dependencies of one process on another (courtesy of Prof. M. Violay).

Testing in-situ

Within ELEGANCY, we have the opportunity to test in-situ the effect of a CO2 injection in a fault, and observe the path flow with a dense monitoring system.

In particular, the aim is to examine and understand the stability of faulted clay, as well as the evolution of the coupling between fault slip, pore pressure, fluid migration and induced “micro” seismicity, if any. Clay is a preferred capturing rock due to its sealing capacity.

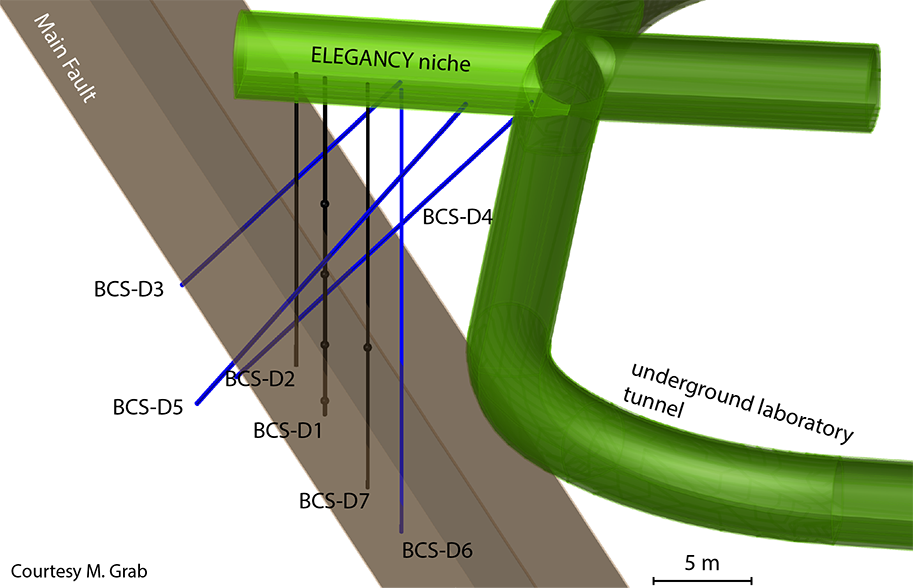

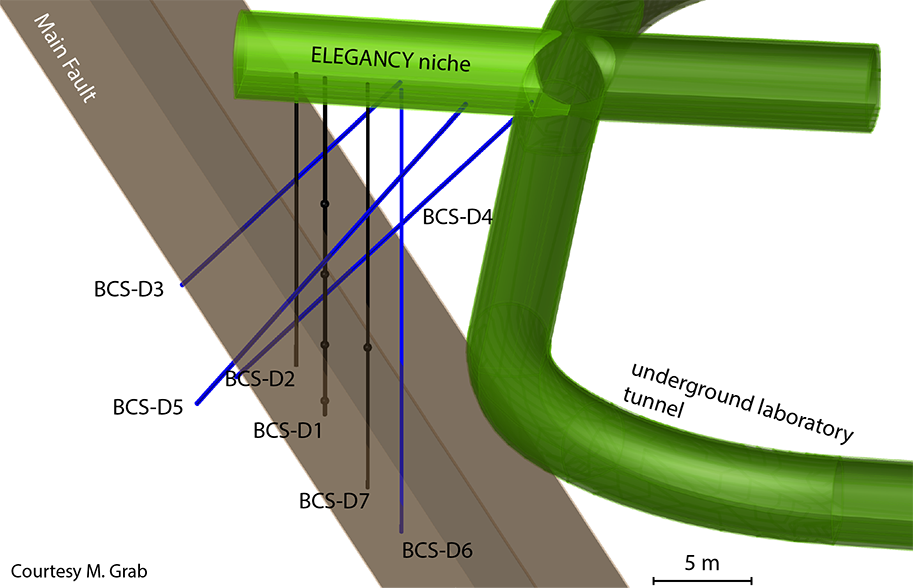

The experiment, supported by simulations at laboratory (cm) scale, and by numerical modelling, will be conducted in the Mont Terri Underground Laboratory. Therein, a fault will be reached and crosscut by an injection borehole and six parallel monitoring boreholes (Figure 2). The uniqueness of the project is to examine the complexity of the coupled processes described above, directly through an in-situ experiment, constrained by fine resolution laboratory experiments and linked at multiple scales via modelling. It will be the first time, CO2 enriched reactive salt water is applied in-situ.

Figure 2: Configuration of the Mont Terry laboratory tunnels, the nice that will be dedicated to the ELEGANCY experiments and the boreholes for injection and monitoring (courtesy of Dr. M. Grab).

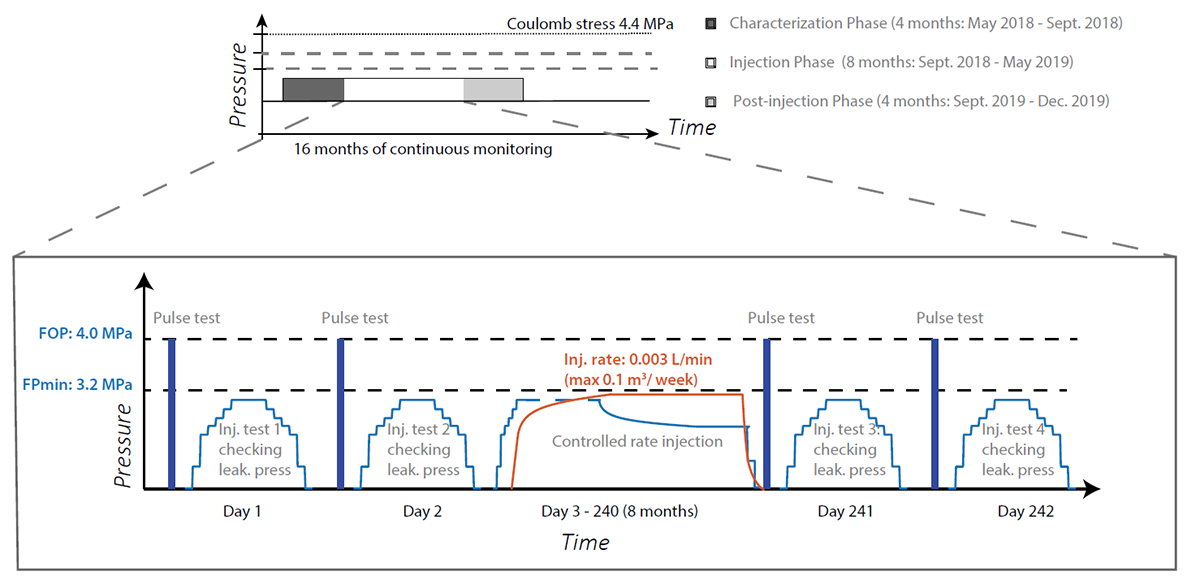

CO2 enriched salt water, and two tracers will be injected in two intervals, one in the core of the fault one in the damaged zone outside of the core, at pressures just below the minimum pressure to open rock bedding planes (32 bar). The injections will be running over a period of approximately eight months.

At the beginning, a few pulse injections at pressures up to the fault opening pressure (40 bar) will be conducted in order to test the response of the fault. The same procedure will be repeated at the end of the eight months to compare the results.

In particular, we will be interested in the activation of aseismic vs seismic slip along the fault, before and after the prolonged exposure to CO2 enriched salt water.

We estimate to inject a maximum volume of a few deciliters of water per week. Just for comparison, at Sleipner (North Sea), the world's first commercial CO2 storage project, approximately 0.85 million tonnes of CO2 is injected each year. Since its inception, over 17 million tonnes have been injected. At another project, Chevron Australia plans to inject between 3.4 and 4 million tonnes of reservoir carbon dioxide per year.

Monitor micro-earthquakes

The monitoring system, placed in the six boreholes surrounding the injection borehole, will observe all operations using different techniques: Active and passive seismic sensors will monitor the variations of seismic velocities around the injection, and register possible micro-earthquakes.

Strain sensors will detect micro-slips in case of fault activation. Electric conductivity and pH-sensors will observe the break-through of the CO2 enriched salt water in the monitoring holes, thus indicating the movement of the injected fluids.

In addition, sampling of rock before and after the injection will provide cores for petrophysical and geomechanical investigation and observation of geochemical changes in the fault rocks. Fluid samplings during the whole injection time will provide material for rock-fluid interaction investigation. The monitoring activities will begin about two months before the injection starts and will end four months after the injection has ended.

Small scale – but better understanding

In contrast to a real, significant CO2 disposal, our experiment only investigates potential leakage on a very small scale. Nonetheless, its findings will contribute to a better understanding of the relevant processes in case of leakage through faults and contribute to an enhanced site characterization.

The experiment involves nine professorships from five academic institutions in Switzerland, all grouped in the Swiss Competence Center for Energy Research - Supply of Electricity.

Authors

Dr. Alba Zappone is a scientist at the Swiss Seismological Service and at the Department of Mechanical and Process Engineering at ETH Zurich. Her research activity is focused on the experimental characterization of physical parameters of rocks at in-situ condition.

Michèle Marti is responsible for media relations and public relations for the Swiss Seismological Service and national and international research projects.